|

Finding the cause of a blocked or broken pipe can be an exceedingly frustrating endeavour. Due to the remote nature involved with inspecting problems that occur in pipelines, it is simply not always feasible to conduct a human inspection.

|

|

Fortunately there are solutions for these types of situations. Through the use of advanced pipeline technology, Rescue Rod is able to conduct remote inspections in nearly any type of pipe. Khuduyane Quigley has a range of CCTV pipe inspection equipment from tractorised high resolution cameras capable of accurately measuring the slope of the pipe in diameters from 100mmØ up to 1500mmØ to pushrod systems capable of inspecting from 80mmØ. We are able to inspect just about any non man entry pipe, tank or vessel up to a distance of 600m. All our operators are trained and certified in using the CCTV Equipment and the Wincan software performing hundreds of pipeline inspections monthly in various industries and projects. |

Equipment and Capabilities:

6 X Push rod endoscope type cameras

2 X Radio detection units with sonde

1 X QuickView system

1 X Digisewer system

1 X Laser Profiler

Applications

Equipment Specifications

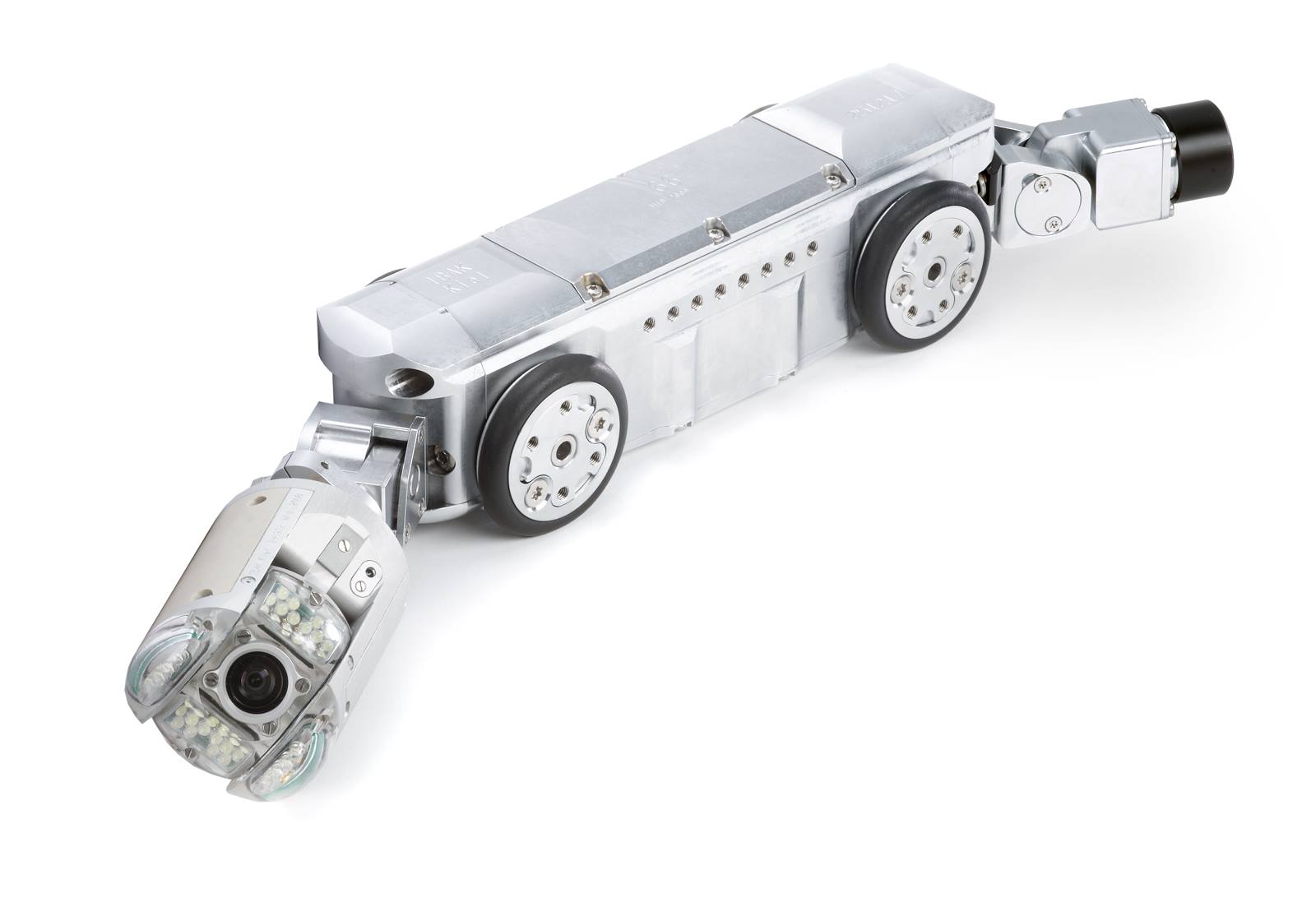

ROVVER X

- Steerable 6-wheel drive maneuvers past obstacles.

- Modular design adapts to pipe of any size, consition and material.

- Compact system footprint can be deployed from any size vehicle.

- Digital controls automatically update to the latest features and support self-diagnostics.

- Scalable design supports lateral launch, side-scanning and laser profiling.

|

This extracted 2D blank gives the operator a perfect overview of the pipe condition and provides an exact localisation and measurement of possible damages, laterals or joints.

The WinCan ScanExplorer features various viewings like front, detail or overview and offers so an easy operation. By featuring a constant speed of the crawler the inspection reduces complexity and saves expensive inspection time.

Your saved inspection data can be sighted afterwards and reported with the WinCan Viewer. Additionally it is possible to extract later measurements out of the data.

|

AGILIOS push camera system

AGILIOS push camera system

DigiSewer® – 190° Inspection System

The DigiSewer® is the perfect add-on to our SUPERVISION®, ROVION®

The DigiSewer® is the perfect add-on to our SUPERVISION®, ROVION®

and ROVVER® inspection systems. Via its additional LED lights, the wide angle “fish eye” lens captures a whole 190° view of the pipe.

The WinCan ScanExplorer generates out of the analog video recordings a 2-dimensional view of the pipes surface.

QuickView®

In addition to the broad range of pipe inspection equipment produced by iPEK we herewith introduce a “zooming camera system” for a “quick view” inside the pipe from the manhole – the QuickView ® from Envirosight – our pipe inspection partner from the U.S.A.

In addition to the broad range of pipe inspection equipment produced by iPEK we herewith introduce a “zooming camera system” for a “quick view” inside the pipe from the manhole – the QuickView ® from Envirosight – our pipe inspection partner from the U.S.A.

Zoom pipe inspection began 15 years ago with QuickView®, and Envirosight has just reinvented the concept with a revolutionary new QuickView® model that outperforms anything on the market. At the core of this new design is patent-pending Haloptic™ technology, a targeting method we’ve devised that doubles inspection range, delivers up to 20 times more illumination, and eliminates the need for incremental realignment.

However, Haloptic™ isn’t the only improvement – the new system also includes a 16 GB polemounted viewer/recorder, an auxiliary manhole camera, and a rugged, waterproof roller case.

Trusted by more than 2000 users worldwide, the patented QuickView® zoom inspection camera evaluates pipelines, manholes and tanks from street level. Contractors use it to survey pipe condition before bidding services, and to document completed work. Municipalities use it to identify and prioritize main tenance issues, avoid confi ned-spaceentry, and inspect hard-to-reach infrastructure. Departments of transportation use it to assess culvert and storm pipe condition with minimal exposure to traffic.

SUPERVISION®

Is valued around the world for its application in all fields of pipeline inspection. Dimension, speed and steerability make SUPERVISION® a powerful inspection tool, thereby being time-saving and moving around obstacles safely.

Is valued around the world for its application in all fields of pipeline inspection. Dimension, speed and steerability make SUPERVISION® a powerful inspection tool, thereby being time-saving and moving around obstacles safely.IBAK Sewer Inspection System

The IBAK T 66 is a versatile camera tractor for the inspection of sewers of DN 100 and up. It can either be used as a portable inspection system or for extending an existing camera tractor system.

It is equipped with the modular IBAK camera connection so that all IBAK cameras can be operated with the T 66. Even when used with the two largest zoom cameras, ORPHEUS or ARGUS 5, it achieves good stability and traction.

In narrow spaces the T 66 copes in combination with the camera connection CC1 that can be panned and folded. Because the folding connector for the camera cable can also be moved horizontally and vertically, the camera tractor can be easily inserted into any pipe of DN 100 and up, as well as through compact manholes and maintenance openings.

WinCan VX

Is the core of the entire WinCan product family. It offers the core functionality you need to collect pipe inspection data, organize it into a database, and generate inspection reports that graphically display the pipe and its defects. WinCan VX also allows you to manage data in the office post-inspection, share it with clients using free viewer software, and export it in a variety of formats. Various report templates present a concise summary of asset condition, and can be fully customized to individual needs.

Is the core of the entire WinCan product family. It offers the core functionality you need to collect pipe inspection data, organize it into a database, and generate inspection reports that graphically display the pipe and its defects. WinCan VX also allows you to manage data in the office post-inspection, share it with clients using free viewer software, and export it in a variety of formats. Various report templates present a concise summary of asset condition, and can be fully customized to individual needs.